VPM-5 SmartPirani™ 真空变送器采用尖端技术打造,不仅提供行业领先的性能表现,更通过将热导式真空计的可用测量范围扩展1-3个数量级,树立了全新的性能标杆。

该产品基于创新的MEMS(微机电系统)传感器技术,结合革命性的高精度数字信号处理架构和先进的测量算法。配合精密的自动化制造与校准工艺,这些技术要素共同成就了一款具有无与伦比测量性能的独特产品。

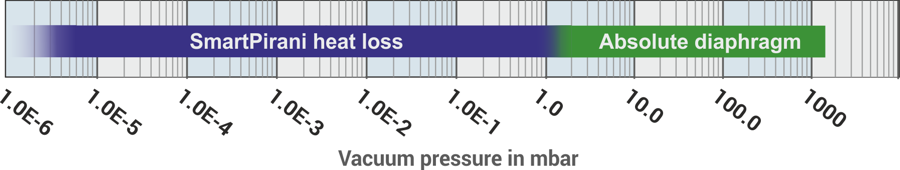

超宽量程覆盖

1.0E-6至1333毫巴,横跨9个数量级

卓越耐腐蚀性能

可选配陶瓷或聚对二甲苯(Parylene)传感器防护层

气体类型无关测量

2至1333毫巴范围内采用精密薄膜传感器技术

极致性价比

为各类真空应用提供业界领先的性能表现

VPM-5-10101211

- DN16KF Flange

- Standard Sensors

- RS-232 Interface

- mbar

- Std. Analog Output

- 1 Setpoint Relay

- 9 pin. D-sub

VPM-5-10201211

- DN16KF Flange

- Standard Sensors

- RS-485 Interface

- mbar

- Std. Analog Output

- 1 Setpoint Relay

- 9 pin. D-sub

VPM-5-10101111

- DN16KF Flange

- Standard Sensors

- RS-232 Interface

- torr

- Std. Analog Output

- 1 Setpoint Relay

- 9 pin. D-sub

VPM-5-10201111

- DN16KF Flange

- Standard Sensors

- RS-485 Interface

- torr

- Std. Analog Output

- 1 Setpoint Relay

- 9 pin. D-sub

领先的真空测量技术

VPM-5 SmartPirani™变送器凭借卓越性能,将热导式真空计的可用测量范围扩展1-3个数量级,重新定义了真空测量的行业基准。

突破性技术解决气体依赖性问题

通过集成MEMS薄膜传感器,SmartPirani™成功消除了传统热导式真空计在粗真空范围内的气体依赖性难题。该传感器提供与昂贵电容式压力计相媲美的测量精度,其测量结果完全不受气体种类和浓度影响。这一技术突破显著提升了测量可靠性,确保真空系统排气过程控制更加精准,有效防止系统过压风险。

严苛工况应用解决方案

针对可能接触腐蚀性或活性气体的应用环境,SmartPirani™可选配高性能防护镀层,为传感器提供可靠保护屏障。

新一代防护技术选项:

• 陶瓷防护层:具有卓越耐腐蚀特性,是经电容式薄膜规验证的真空传感器膜片材料

• 聚对二甲苯(Parylene)防护层:独特聚合物材料兼具超强耐腐蚀性和疏水特性,专为冻干灭菌等医疗应用设计

颗粒防护创新设计

针对存在颗粒污染的真空工艺,SmartPirani™可配备防护挡板,有效阻隔宏观颗粒物。结合可选防护镀层技术,新一代变送器专为应对极端真空环境挑战而打造。

Specifications | |

| Measuring range in mbar | 1×10-6 to 1333 mbar (7.5×10-7 to 1000 Torr) |

| Measuring principle 1×10-6 to 1.5 mbar | MEMS Pirani thermal conductivity |

| Measuring principle 1.5 to 2 mbar | Blended MEMS Pirani / piezo reading |

| Measuring principle 2 to 1333 mbar | MEMS piezo resistive diaphragm |

| Accuracy 1×10-5 to 9.99×10-5 | 25% of reading |

| Accuracy 1×10-4 to 7.99 mbar | 5% of reading |

| Accuracy 8.00 to 99.9 mbar | 1% of reading |

| Accuracy 100 to 800 mbar | 0.5% of reading |

| Accuracy 800 to 1099 mbar | 0.25% of reading |

| Accuracy 1100 to 1333 mbar | 0.5% reading |

| Hysteresis 1×10-3 to 10 mbar (ISO19685:2017) | 1% |

| Hysteresis 10 to 1333 mbar (ISO19685:2017) | 0.1% |

| Analog output resolution | 16 bit (150 μV) |

| Analog output update rate | 124 Hz |

| Response time (ISO 19685:2017) | <20 ms |

| Temperature compensation | +10 to +50 °C |

| Solid state relay set point range | 5×10-6 to 1333 mbar (3.75×10-6 to 1000 Torr) |

| Solid state relay contact rating | 50 V, 100 mArms / mADC |

| Solid state relay approvals | UL Recognized: File E76270 CSA Certified: Certificate 1175739 EN/IEC 60950-1 Certified |

| Environment conditions | |

| Operating ambient temperature | -20 to +50 °C |

| Media temperature | -20 to +50 °C |

| Storage ambient temperature | -40 to +120 °C |

| Bake-out temperature (non-operating) | +120 °C |

| Maximum media pressure(3) | 10 bar absolute |

| Mounting position | Arbitrary |

| Protection rating, EN 60529/A2:2013 | IP40 |

| Humidity, IEC 68-2-38 | 98%, non-condensing |

| Power supply | |

| Supply voltage | 12-30 VDC |

| Power consumption | 240 mW (max) |

| Reverse polarity protection | Yes |

| Overvoltage protection | Yes |

| Internal fuse | 100 mA (thermal recoverable) |

| Materials | |

| Enclosure | SS 1.4307 / AISI 304L / Aluminum 6061 |

| Vacuum Process flange (media wetted) | SS 1.4401 / AISI 316 |

| Vacuum exposed materials (media wetted) Standard version | 316 Stainless steel, Kovar, glass, silicon, nickel, aluminum, SiO2, Si3N4, gold, Viton®, low out-gassing epoxy resin, solder, RO4305 |

| Vacuum exposed materials (media wetted) Parylene protected version | 316 Stainless steel, Viton®, Parylene |

| Vacuum exposed materials (media wetted) Ceramic protected version | 316 Stainless steel, Viton®, Aluminum oxide ceramic (AI2O3) |

| Process leak tightness | <1·10-9 mbar·l/s |

| Reliability | |

| MTBF (Mean Time Between Failure) | 13.092.170 hours |

| Failure rate FIT (Failure In Time, where time=10E+9 hours) | 76,38 |

| Approvals | |

| CE | EMC directive 2014/30/EU |

| RoHS compliance | Directive EU 2015/863 |