VPM-4 SmartPirani™ Lite真空变送器

| 真空测量 |

VPM-4 MEMS皮拉尼传感器

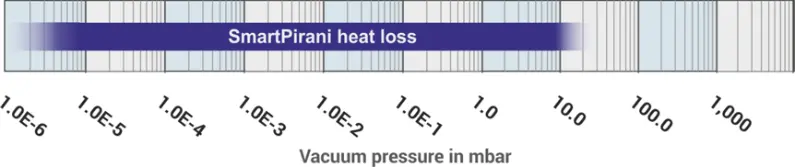

宽量程MEMS皮拉尼传感器,测量范围1.0E-6至10毫巴

耐腐蚀性能

可选陶瓷或聚对二甲苯传感器保护层

数字接口

配备RS-232和RS-485数字接口,便于系统集成

过程控制

可编程设定点继电器,实现真空开关功能

VPM-4 SmartPirani™ Lite真空变送器采用尖端技术,提供行业领先的性能表现,通过将热导式真空计的可用测量范围扩展1-3个数量级,树立了新的性能标准。

SmartPirani™采用先进的MEMS(微机电系统)传感器技术,结合前沿数字信号处理架构与创新测量算法。配合精密自动化制造与校准工艺,打造出这款性能无与伦比的独特产品。SmartPirani™ Lite专为真空开关功能设计,测量上限为10毫巴。若需覆盖至大气压及更高压力的全量程测量,请选择VPM-5 SmartPirani™变送器。

领先的真空测量技术

VPM-4 SmartPirani™ Lite变送器以卓越性能重新定义真空测量标准,将热导式真空计的可用测量范围突破性扩展至1E-6量级。

VPM-4测量范围

SmartPirani™ Lite的扩展量程使其能应用于传统需热阴极电离规或冷阴极电离规的领域。该产品针对低量程测量性能进行优化,上限测量范围可达10毫巴(7.5托)。

SmartPirani™变送器系列还包含:

- 全量程VPM-5 SmartPirani™:提供2至1333毫巴的气体无关性测量

- VPM-7 SmartPirani™ ATM:额外配备大气压开关功能

应对严苛应用的卓越性能

为适应腐蚀性及活性气体环境,SmartPirani™可选配防护镀层,为传感器提供高效保护屏障。

多重防护解决方案

SmartPirani™变送器系列现提供陶瓷或聚对二甲苯(Parylene)防护层选项,有效防止传感器材料腐蚀氧化:

- 陶瓷镀层:具有极强耐腐蚀性,广泛用于电容式薄膜规等真空传感器膜片

- 聚对二甲苯镀层:独特聚合物材料兼具卓越耐腐蚀性与疏水特性,特别适合冻干灭菌等医疗应用

颗粒防护设计

针对存在颗粒物的真空工艺环境,SmartPirani™可加装防护挡板阻隔宏观颗粒。结合可选防护镀层技术,新一代变送器专为在极端真空环境中稳定运行而设计。

Specifications | |

| Measuring range in mbar | 1×10-6 to 10 mbar (7.5×10-7 to 7.5 Torr) |

| Measuring principle 1×10-6 to 10 mbar | MEMS Pirani thermal conductivity |

| Accuracy 1×10-5 to 9.99×10-5 | 25% of reading |

| Accuracy 1×10-4 to 9.99×10-1 mbar | 5% of reading |

| Accuracy 1.00 to 10 mbar | 30% of reading |

| Hysteresis 1×10-3 to 10 mbar (ISO19685:2017 | 1% |

| Analog output resolution | 16 bit (150 μV) |

| Analog output update rate | 124 Hz |

| Response time (ISO 19685:2017) | <20 ms |

| Temperature compensation | +10 to +50 °C |

| Solid state relay set point range | 5×10-6 to 1333 mbar (3.75×10-6 to 1000 Torr) |

| Solid state relay contact rating | 50 V, 100 mArms / mADC |

| Solid state relay approvals | UL Recognized: File E76270 CSA Certified: Certificate 1175739 EN/IEC 60950-1 Certified |

| Environment conditions | |

| Operating ambient temperature | -20 to +50 °C |

| Media temperature | -20 to +50 °C |

| Storage ambient temperature | -40 to +120 °C |

| Bake-out temperature (non-operating) | +120 °C |

| Maximum media pressure(3) | 10 bar absolute |

| Mounting position | Arbitrary |

| Protection rating, EN 60529/A2:2013 | IP40 |

| Humidity, IEC 68-2-38 | 98%, non-condensing |

| Power supply | |

| Supply voltage | 12-30 VDC |

| Power consumption | 240 mW (max) |

| Reverse polarity protection | Yes |

| Overvoltage protection | Yes |

| Internal fuse | 100 mA (thermal recoverable) |

| Materials | |

| Enclosure | SS 1.4307 / AISI 304L / Aluminum 6061 |

| Vacuum Process flange (media wetted) | SS 1.4401 / AISI 316 |

| Vacuum exposed materials (media wetted) Standard version | 316 Stainless steel, Kovar, glass, silicon, nickel, aluminum, SiO2, Si3N4, gold, Viton®, low out-gassing epoxy resin, |

| Vacuum exposed materials (media wetted) Parylene protected version | 316 Stainless steel, Viton®, Parylene |

| Vacuum exposed materials (media wetted) Ceramic protected version | 316 Stainless steel, Viton®, Aluminum oxide ceramic (AI2O3) |

| Process leak tightness | <1·10-9 mbar·l/s |

| Reliability | |

| MTBF (Mean Time Between Failure) | 13.092.170 hours |

| Failure rate FIT (Failure In Time, where time=10E+9 hours) | 76,38 |

| Approvals | |

| CE | EMC directive 2014/30/EU |

| RoHS compliance | Directive EU 2015/863 |